The osb and in fact any wood panels must be allowed to dry completely depending on how wet the panels are this could be a few days before any roofing material is applied to avoid trapping moisture under the roof material that could cause edge swell and buckling.

Osb roof sheathing got wet.

And next time specify advantech.

Here are the four main ways you get wet framing lumber to dry.

With the shingles on it sill still breathe.

If the osb swelling is too serious more than your belt sander can fix install a layer of tongue and groove plywood over the ruined osb.

Installing dry is virtually impossible in rainy climates however brief periods of wetting should not cause decay problems provided osb dries below 16 before the air barrier and cladding are both added.

Osb roof sheathing gets rained on all the time up here and roofs are the first cover to go on a framed structure.

Houses i built got wet.

Although plywood is usually more expensive than osb plywood is more resistant to moisture damage.

15 and 30 felts will breathe.

Unfortunately more rain is heading this way for the next four days.

When the air underneath circulates it will dry.

Allowing osb to get wet is not a wonderful idea but its done all the time.

If you live in an especially rainy or humid climate consider using plywood sheathing instead of osb.

Use a dehumidifier 4.

I worked all day yesterday installing the osb roof sheathing in hopes of getting the roofing felt on before it started raining.

Under the best circumstances the osb sheathing is delivered to the site installed and covered within a few days.

When the sun shines it dries.

I have noticed that osb that has ever been wet will discolor and it weakens it a lot as if it had much in structural strength to begin with.

I suppose if it was wet and then protected immediately it would still be ok you know no water no rot the damage would all show up soon.

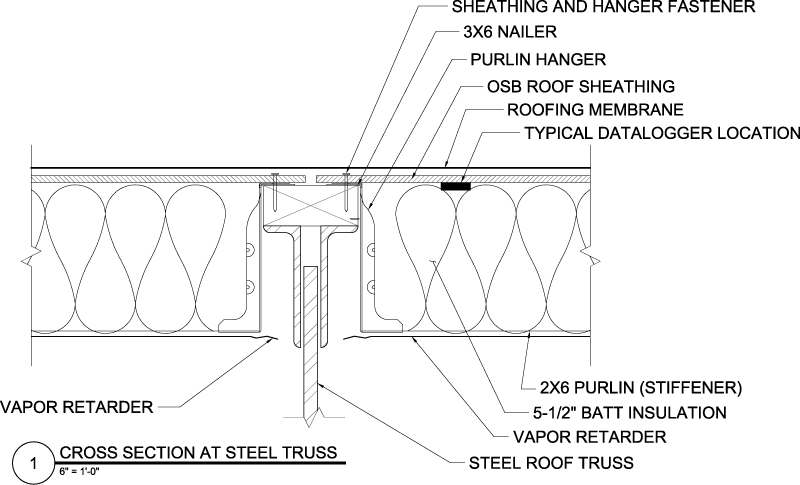

Thermostat 7 16 cat ps2 10 osb sheathing application as 4 x 8.

It poured last night leaving the osb drenched.

Osb sheathing 15 32 cat ps2 10 osb sheathing application as 4 x 8.

The glues used to make osb are water resistant because the manufacturers know that virtually no one can build a home that won t get wet before the roof and siding is applied.

Once the house is dried in and the osb has dried out use a belt sander to take down the swollen edges of the osb.

The underside will breathe.

For pricing and availability.